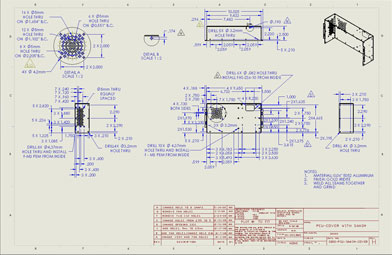

Our Engineering team works hand in hand with its customers to gain a comprehensive understanding of their engineering and business goals, and translates those goals into innovative, creative, and successful product designs. Whether we are working from sketches, drawings, prototypes, and/ or old parts, we enhance our customer's ability to effectively visualize concepts and transform them into reality. From start to finish, our comprehensive knowledge of practical manufacturing methodologies heavily contributes to the successful drafting and designs we create for our customers. Our design for manufacturability approach to product design, results in a cost effective strategy for success.

Why choose our engineering services?

We want to understand your products from design through manufacturing and offer solutions to help your company be strong in this competitive market. Our engineers use state of the art CAD software. We can work with wide range of file types and import them in to our CAD system.

We can Reverse Engineer your existing parts and turn them in to CAD. Using a FARO Laser ScanArm free form surfaces can be rapidly scanned to produce a point cloud. This can be triangulated and surfaced using our Delcam software. Our touch probe FaroArm can also be used to record and reproduce geometric parts.

In many fields, there is great uncertainty as to whether a new design will actually do what is desired. Therefore our companies often uses prototypes as part of the product design process to allow engineers and designers the ability to explore design alternatives, test theories and confirm performance prior to starting production of new product.

Ultimately, the more successful you are as a customer, the more successful we are as a company.

To see our designs, click here.